Company news

- 热门产品

- 热门新闻

- What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mol

- What problems will PVC plates formed by gusset mold encounter?

- In what fields are gusset dies used?

- Plug mold caused by temperature of profile mold

- What are the conditions of mold plugging caused by unreasonable design of profile mold?

- KEYWORD

What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mol

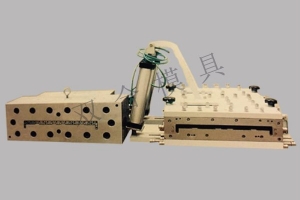

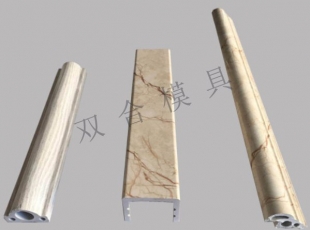

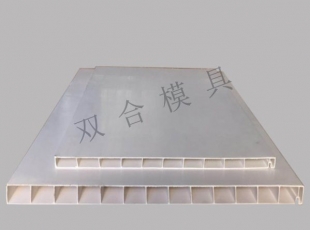

What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mold?The general name of aluminum gusset plate processing equipment is integrated ceiling machine,also known as integrated ceiling equipment,integrated ceiling hydraulic machine,integrated ceiling production equipment,but it is a supporting mechanical product.In addition to the integrated ceiling mold,it is called integrated ceiling machine.If you want to choose a good integrated ceiling machine,in addition to the quality of the hydraulic machine,the key is the quality,accuracy and service life of the supporting mold,Whether the four corners of the punched aluminum gusset plate are tightly sewn.

Details to pay attention to when purchasing an integrated ceiling machine:

The selection of integrated ceiling mold is very important.If the mold is selected,it is equivalent to producing qualified aluminum gusset plates.Yingdefeng's advantage is that the manufacturer has its own CNC mold opening equipment to ensure accuracy and after-sales service.In terms of the price of integrated ceiling equipment,yingdefeng's price is a little higher than that of other manufacturers,but the quality and service life are completely different.Yingdefeng's hydraulic machine is repaired free of charge for one year,The mold is free of charge for life.

At present,the new integrated ceiling aluminum gusset plate one-time forming equipment adopts double-layer oil cylinder,which has the function of fast and slow speed,fast no-load travel,saves time and increases the working space for placing materials,shortens the time for placing aluminum plates and removing finished products,and increases work efficiency.The machine adopts the circuit board control system,enhances the safety coordination system,and has a higher level of safety protection.The hydraulic system has pressure relief device,rapid liquid filling device,and the use of pressure relay makes it have the characteristics of adjustable pressure and no adjustment of thick plate and thin plate.

The integrated ceiling aluminum gusset plate primary forming equipment adopts the clutch angle cutting and delay hydraulic cylinder return system,which,together with the photoelectric system,replaces the spring angle cutting and spring return in the traditional secondary forming equipment,and solves the disadvantages of uneven spring pressure,broken spring steel causing knife edge damage,and replacing the spring due to the inertia of the spring.There is no need to replace spare parts frequently,and the maintenance cost is lower.The appearance of stamped aluminum products is flat,straight,beautiful and generous,Seamless splicing is one of the necessary equipment for processing aluminum gusset plate of integrated ceiling in home decoration.

Who is the manufacturer of integrated ceiling equipment and integrated ceiling mold,and what are the manufacturers now?Customers who want to open aluminum gusset plate processing plants must choose the equipment mold.If they choose the wrong one,it will be very troublesome.How to choose a high-quality integrated ceiling machine manufacturer?At present,there are not many manufacturers with certain scale and good brand in the factory's production technology,quality assurance,after-sales service and company,As far as yingdefeng knows,the manufacturers of integrated ceiling production equipment are relatively integrated in Guangdong.However,compared with the south,there are no well-known manufacturers of integrated ceiling equipment in the north,and they are not very concentrated,and everyone is not very familiar with them.

The preferred manufacturer for customers to buy machines should have CNC machining centers,and the precision of CNC mold opening should be high,so as to ensure that one side of the produced aluminum gusset plate is tightly sewn to any four sides.The main structure of yingdefeng mold is made of 45#steel Cr12MoV material,which has a longer service life after vacuum heating treatment process.All vulnerable parts such as guide parts and springs are imported accessories,with a service life of more than one million strokes,an angular position height error of less than 10cc,and the folding forming angle is between-0.5°and-2°.The angle can also be adjusted freely according to customer requirements and raw materials(such as roller coated plate,sanding plate,oxide plate,etc.).

At present,the high sales volume of integrated ceiling aluminum gusset equipment in the market is still the one-time forming equipment of integrated ceiling aluminum gusset plate.Previously,some customers who produce aluminum gusset plate,iron plate and three-dimensional gusset plate used the secondary forming equipment of integrated ceiling aluminum gusset plate,but they need the secondary pressing process,which wastes half of the labor cost and electricity cost more than the one-time forming equipment.In the market with relatively weak profit space,Choosing the primary forming equipment of integrated ceiling aluminum gusset plate is a clear choice.With the upgrading of integrated ceiling machines in the market,the primary forming equipment of integrated ceiling aluminum gusset plate will replace the secondary forming equipment of integrated ceiling aluminum gusset plate.

Keyword:gusset plate,mold

Article source:http://www.wx-mould.cn/

上一页:没有了…