Industry news

- 热门产品

- 热门新闻

- What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mol

- What problems will PVC plates formed by gusset mold encounter?

- In what fields are gusset dies used?

- Plug mold caused by temperature of profile mold

- What are the conditions of mold plugging caused by unreasonable design of profile mold?

- KEYWORD

How to improve the surface brightness of PVC profile mold

How to improve the surface brightness of PVC profile mold

Gb/t8814-2004 clearly stipulates the appearance quality of profiles.Although no specific value or grade of surface brightness is proposed,the surface brightness of profiles has attracted more and more customers'attention.There are many factors that affect the surface brightness of profiles,and some of them restrict each other and complement each other.This paper studies and analyzes several main factors affecting the surface brightness of profiles through experiments.

Test part

1.Main test equipment

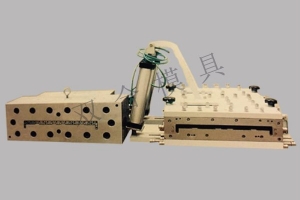

Cold and hot mixing unit,srl500-1000 type,Zhangjiagang plastic equipment factory;Twin screw extruder,65/132 type,Shanghai Jinhu extrusion equipment Co.,Ltd;Push pull 80 frame mold,type 80,Jiangsu Jerry mold factory.

2.Main test raw materials

PVC,brand qs-1050p,Qilu Petrochemical;CPE,brand h135a,produced in Weihai,Shandong;Lubricant,produced in Chengdu;Activated calcium carbonate,produced in Jingxing,Shijiazhuang;Color Masterbatch,produced in Shunde,Guangdong.

3.Test procedure

Based on the quality of 100 parts of PVC resin,accurately weigh various test raw and auxiliary materials according to the test formula.After the prepared material is mixed by the cold and hot mixing unit with the same process,the profile is continuously extruded on the twin-screw extruder-push-pull 80-k.In the experiment,the extrusion process remained basically unchanged:barrel temperature,170~180℃;Die temperature,180~190℃.According to the surface brightness of extruded profiles,the influence of various factors on the surface brightness is discussed.

Analysis and discussion of test results

1.Effect of active calcium carbonate content on surface brightness of profile

Fillers are essential in the production of profiled materials.They can not only reduce the cost,but also improve some properties of profiled materials,such as the reduction of dimensional change rate and the improvement of rigidity after heating.Activated calcium carbonate is a commonly used filler in profile production,and its dosage affects the surface brightness of profile.

When the amount of active calcium carbonate is 15 kg,the profile performance is qualified and the surface brightness is good.When the dosage is increased to 20kg,although the profile performance test is qualified,the surface brightness decreases significantly,because the active calcium carbonate has a high oil absorption value.After excessive addition,the active calcium carbonate absorbs the lubricant in the profile formula,thereby reducing the surface brightness of the profile.

2.Influence of the amount of PE wax on the surface brightness of profile

PE wax is a common external lubricant.In the process of processing,under the action of pressure,it is easy to extrude from the mixed materials and migrate to the surface.The PE molecules are oriented and arranged,and the polar groups face the metal surface.Through physical adsorption and chemical bonds,a lubricant molecular layer is formed.Therefore,it can reduce the friction between the polymer and the equipment surface and improve the surface brightness of the profile.

When the amount of PE wax is 0.2 parts,the performance of the profile is qualified,but the surface brightness is poor.When the dosage is increased to 0.4 phr,the extrusion plasticization of the profile is good,the performance test is qualified,and the surface is bright.However,when the dosage is increased to 0.6 phr,the extrusion of the profile is difficult,the plasticization of the material is poor,and the performance test is unqualified.This is because too much lubricant is added to form a layer of isolation film,and there will be slippage between the mixed materials and the equipment.The materials cannot get the shear stress due to plasticization and cannot be plasticized well.Therefore,the profile performance test is unqualified,and the surface brightness decreases instead.Therefore,a reasonable amount of lubricant is the key to ensure the performance and surface brightness of the profile.

3.Influence of ACR dosage on surface brightness of profile

ACR,as a processing aid,can improve the molding and processing properties of rigid PVC.The addition of it can improve the friction coefficient between the resin and the machine,make the hard PVC change from sliding wall body to sticking wall body,increase the shear stress,and the material is well plasticized,so as to have good surface brightness.

When the dosage of ACR in the formula is 0.5 parts.The surface brightness of the profile is poor,and the physical properties are also unqualified.This is because the amount of ACR is too small to turn PVC into a wall adherent,and the material can not get enough shear stress and can not be plasticized well.Therefore,the physical properties and surface brightness of the profile are poor.When the amount of ACR is large,the material can get enough shear stress and good plasticization.Therefore,the physical properties and surface brightness of the profile are improved.However,the more ACR is used,the better,because the addition of ACR can accelerate the plasticization process of materials.If the material is plasticized too early,part of the material will be decomposed before the extrusion die,which will also reduce the surface brightness of the profile.Therefore,finding out the appropriate amount of ACR and making it cooperate well with other additives will greatly improve the surface and internal properties of the profile.

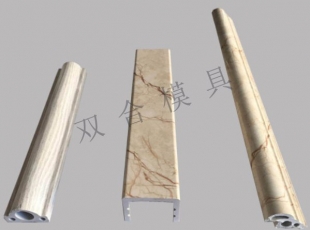

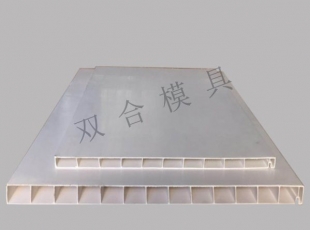

4.Influence of mold surface quality on surface brightness of profile

Mold is one of the core equipment in profile extrusion production.The surface quality of mold directly affects the surface brightness of profile,especially the surface quality of setting mold.Because after the hot parison enters the mold,it is shaped into products through vacuum adsorption and cooling.Due to the effect of vacuum adsorption,in the setting mold,the surface of the parison moves against the surface of the setting mold.If the surface polishing quality of the setting die is not good,it will inevitably lead to the decline of the surface quality of the profile.In addition,during the use of the setting mold,due to improper maintenance or material corrosion,the smoothness will also be reduced,which is bound to affect the surface quality of the profile.Therefore,the quality of mold surface is an important factor affecting the surface brightness of profile.

Conclusion

(1)Whether the dosage of active calcium carbonate,PE wax and ACR in PVC profile mixture is appropriate has a great relationship with the surface brightness of the profile.

(2)The polishing quality of mold surface is an important factor affecting the surface brightness of PVC profile;In addition,the mold should be well maintained to maintain its surface finish.

Because we are professional,we are excellent!

Because of you,we will be more wonderful!

上一页:How to improve the surface brightness of PVC profile mold

下一页:Analysis and treatment of die plugging of aluminum extrusion die and case practice analysis