Industry news

- 热门产品

- 热门新闻

- What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mol

- What problems will PVC plates formed by gusset mold encounter?

- In what fields are gusset dies used?

- Plug mold caused by temperature of profile mold

- What are the conditions of mold plugging caused by unreasonable design of profile mold?

- KEYWORD

Maintenance and repair of profile mold

Maintenance and repair of profile mold

1 Overview

Extrusion die is an important forming equipment for producing extruded profiles.It is a forming and shaping equipment to ensure the size and shape quality of profiles under the stable external process and equipment environment,such as stable raw material formula,stable extruder operation,stable sizing table vacuum and water pressure,stable water temperature and circulating water flow,stable tractor operation,etc.Mold maintenance is the most basic guarantee to ensure the normal production of molds,and the basis to further improve the performance of molds and further improve the level of mold design,manufacturing and debugging.We should be careful and correct in mold maintenance and repair,and try to reduce the impact of mistakes in basic mold maintenance and repair operations on the further correct analysis of mold design and manufacturing.Although the mold maintenance is neither a high-tech technology nor a difficult operation,it cannot be said that it is simple and unimportant.Zhang Ruimin,President of Haier Group,has a famous saying:what is not simple?It is not simple to be able to do simple things right thousands of times;What is not easy?It is not easy to do well what is generally recognized as a very easy thing.Therefore,the maintenance of the mold is neither simple nor easy.

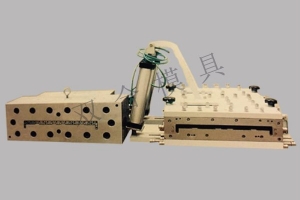

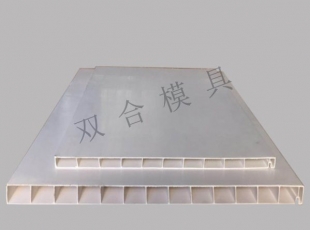

2.The basic elements of forming an extrusion die:there are three basic elements of forming an extrusion die:first,the shape and size of the die cavity(including the die runner and the stereotypes cavity)and the gradual change law of the cavity size;2、Cooling water circuit design of setting die;3、Design of the air circuit of the vacuum adsorption of the setting mold.On the basis of ensuring the correctness and effectiveness of these three elements,considering the feasibility of processing and manufacturing cost,the rationality of the interface with the equipment,the convenience and firmness of frequent disassembly and installation,the convenience and accuracy of debugging,maintenance and cleaning,it is required to have a reasonable typing method for different parts of the mold,a reasonable water and gas path sealing and blocking method,a reasonable connection method between various components,and an accurate,wear-resistant and easy disassembly positioning method,And a firm tightening method.Therefore,in addition to the three basic elements,the structural form,parting mode,assembly mode,use of different accessories,connection mode of various parts,interface form with extrusion and sizing equipment,and other aspects of the extrusion mold also need us to understand through continuous understanding and contact with new molds in the process of maintenance,so as to ensure that we can maintain every mold accurately.

3.During the forming process of plastic profile,we should carefully understand the changes and laws of a series of energy and physical properties in the process of plasticized irregular shaped materials entering the mold for shunting,compression until they are out of the mold through adapter reducer,and then entering the setting mold for cooling and shaping,and finally becoming qualified profile.This will enable us to grasp the principles and norms that should be followed in the process of mold maintenance and repair,Thus,we can draw inferences from one instance to deal with possible problems that we have never encountered

3.1 process 1.Reducing in the process of mold design,the diameter of the mold inlet is usually designed according to the outlet diameter of the extruder that can reach 1.25--1.5 times the extrusion capacity of the mold design,so there is usually no problem of reducing.However,when the actual model used is too large or too small,or when the cross-section size of the profile is too large or too small,resulting in the design requirements of the mold channel to have too large or too small inlet,the problem of reducing diameter arises.Knowing the existence of reducing,we can consider and pay attention to the matching between the die and the equipment interface when installing the die,so as to avoid errors in the installation process

3.2 process 2.The main function of the extrusion die head is to gradually turn the columnar melt extruded from the extruder into the parison fluid interconnected in the form of sheet fluid.The two processes of diversion and compression ensure the realization of the main function of the machine head.In the process of flowing from back to front in the runner,the melt has the characteristic of memory for the change of the runner section shape,which makes the shape of the billet after leaving the die different from that of the die to a certain extent.The size of the difference depends on the length of the straight section of the die.The longer the straight section,the smaller the difference

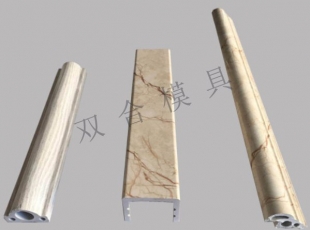

3.3 process 3.After the softened melt parison leaves the die for extrusion,the final determination of its size and shape is finally achieved through the gradual cooling of the qualitative die and the cooling water tank.To ensure that the profile has the correct shape and qualified size,the following conditions should be met for the setting die:first,the correct inlet shape and size;2、Correct cavity size and size change law;3、Correct cavity shape;4、Sufficient cooling rate;5、Sufficient adsorption capacity.

4.Principle of mold maintenance maintenance refers to checking whether there is damage and whether it needs to be repaired or replaced;Maintenance refers to cleaning,derusting and polishing.The most basic operation is disassembly and installation.In the daily mold maintenance and service work,the following principles should be implemented all the time.

上一页:What about bubbles in products with thick PVC profile mold?

下一页:Analysis of common problems in debugging PVC profile extrusion die