Industry news

- 热门产品

- 热门新闻

- What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mol

- What problems will PVC plates formed by gusset mold encounter?

- In what fields are gusset dies used?

- Plug mold caused by temperature of profile mold

- What are the conditions of mold plugging caused by unreasonable design of profile mold?

- KEYWORD

What about bubbles in products with thick PVC profile mold?

What about bubbles in products with thick PVC profile mold?

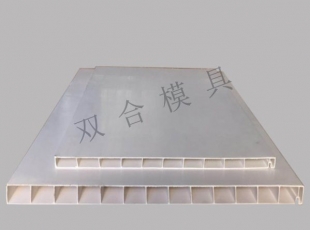

Because the thickness of PVC profile mold products is different,bubbles often appear in the thick part,and bubbles are easy to appear at the joint.The surface part of the product is cooled first in the model.The center usually cools very slowly.When the center part cools,it will shrink.However,because the surface has been cooled,it can only shrink by itself to form bubbles.Many thick products have no bubbles when they are out of the mold,but after more than ten seconds,bubbles will appear in the center.

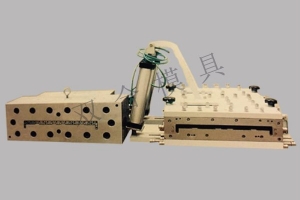

PVC profile mold

What are the reasons for the bubble problem of plastic profile?Let's take a look

1:Thick products have fat and bulging surfaces,and there are bubbles at the sawn section.The reasons may be:

1)The injection speed is too fast to exclude the air and form bubbles.

2)This phenomenon will also occur if the feeding amount is too much or too little,and the injection pressure is too high.If the feeding amount is adjusted appropriately,this phenomenon will be improved.

3)The cooling time is too short(especially for thick wall products),and the solution can be to use cold water and cold dies outside the machine for cooling.

4)There are decomposition black lines in products,which are formed due to high temperature.

5)This phenomenon also occurs when the gate of the mold is too small and the exhaust is poor.

2:Solid products have holes and blackening.When solid products are molded,the injection pressure should be low and the injection speed should be slow.Otherwise,the air will be wrapped in the products through friction and scorch under high pressure,so that there will be black voids in the products.Therefore,properly reduce the injection pressure and injection speed,and the cavity phenomenon will disappear.You can also check whether the feeding amount is too much.Appropriately reducing some feeding amount is also beneficial to improve this phenomenon.

3:When the thickness of plastic profile products is different,there are small bubbles in the thicker part of the products,or there are black bubbles in the thick part of the products.When forming several products with different shapes at the same time,it must be noted that the size of each gate should be equal to the weight of the product,otherwise,thick products are easy to produce bubbles.At the same time,pay attention to the exhaust of the mold.The products often left on the front mold make it difficult to exhaust,which is easy to produce the above phenomenon.This phenomenon can be improved by modifying the mold or increasing the pressure holding time and cooling time to reduce the insufficient pressure on the cross-section of the thickness reinforcement.More importantly,when designing products,we should try to avoid extra thick parts of products.

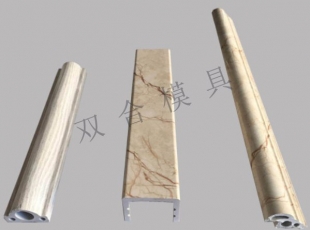

According to the above introduction,we can learn that in order to avoid bubbles in PVC profile mold products,we should try not to make the products appear too thick.In case of thick places,the injection speed should be avoided too fast,and the feeding amount should also be controlled to avoid excessive pressure.Extend the cooling time,and use cold water to cool down outside the machine.Improve the mold exhaust effect.Wuxi Shuanghe mould is specialized in manufacturing and designing all kinds of PVC profile extrusion moulds.It has a variety of production moulds,excellent quality,strong technical force and rich production experience.Widely praised and trusted by customers.