Industry news

- 热门产品

- 热门新闻

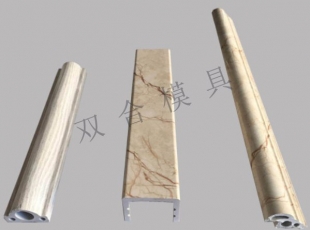

- What should we pay attention to when purchasing aluminum gusset plate production equipment and aluminum gusset plate mol

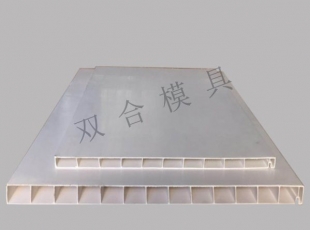

- What problems will PVC plates formed by gusset mold encounter?

- In what fields are gusset dies used?

- Plug mold caused by temperature of profile mold

- What are the conditions of mold plugging caused by unreasonable design of profile mold?

- KEYWORD

What are the key points of PVC gusset mold installation?

What are the key points of PVC gusset mold installation?

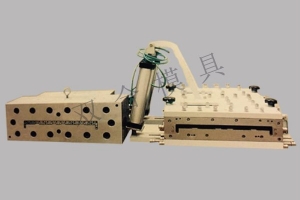

The pipe mold structure used in the production of UPVC solid wall pipe by twin-screw extruder is roughly the same,which is generally composed of front mold body,support,rear mold body,splitter shuttle,die,mandrel,etc.the function of the machine head is to continuously provide the molten plastic melt with a certain pressure by the extruder to enter the die through its specific channel to form a tube embryo with annular section,and then get the required pipe after cooling and shaping.

1、Key points of mold installation:

When grinding the mold,use metallographic fine sand.In case of serious corrosion,use water to grind and polish the rust,and then use fine sand paper or polishing machine to polish.The support should be polished thoroughly without dead corners and yellow lines.The connection of the mold should be smooth and flat without burrs and dead corners.The screw holes of the mold should be cleaned regularly to prevent molybdenum disulfide from carbonization,and the screws are not easy to disassemble and assemble;

Upper mold:before the mold is installed on the machine,all tools and some necessary items should be prepared,whether the filter plate should be added with copper,whether the belt and iron chain used to hang the mold should be checked for integrity,and the mold should be horizontal.During the mold installation,the feet and other parts of the body should not be under the mold,and the thermocouple hole should preferably be above;

Before installing the gusset mold,you should first find out the mark,and then assemble it according to the mark.During the assembly process,you must pay attention to safety.Be careful when using the crane,and the action should be light to avoid personal injury and mold damage.When installing the screws,check each bolt,thread and hardness.Replace the bad screws in time,and smear an appropriate amount of molybdenum disulfide on each screw;

Tightening the mold:tighten the bolts of the mold before starting the machine.When tightening the bolts,tighten the screws of the mold base first,and then tighten the pressing plate.The wall thickness.When tightening the bolts,one person is required to tighten the bolts diagonally with uniform force.

2、Precautions for pipe mold selection:

Due to the fast production speed of the first mock examination double output,when choosing mandrel,medium mandrel is generally used as light pipe and heavy mandrel as medium pipe.

Single output can also adopt double output method,and the one with the smallest diameter can also be selected from many mandrel.Generally,short die mandrel is used for light weight,and long die is used for medium and heavy weight;The drainage pipe mold is generally a special mold.

上一页:Development of profile mold industry in China

下一页:What are the requirements of gusset plate mold design and production